W MoSi2 heating elements

W Type Heater of Molybdenum disilicide MoSi2 heating elements.

For applications where the furnace roof is particularly low, the use of horizontally mounted elements can be used. In such cases, four-shank elements might be used where the surface temperature of the element will not exceed 1800 deg C. Available in Grade MD-31 in 3/6, 4/9, 6/12, 9/18 and 12/24 sizes. The multi-shank elements have advantages over two-shank elements in that the hot zones are longer, therefore fewer elements can be used and the cold end losses are reduced.

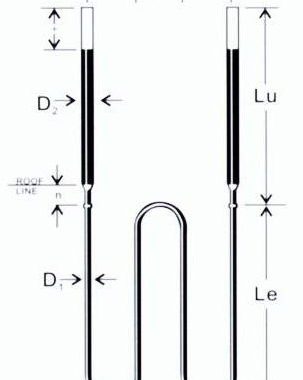

W Type heating elements molybdenum disilicide MoSi2 heater MoSi2 Heating Elements are described by:

Grade: 1700, 1800 or 1900

Diameter: D1/D2, mm/mm

Heated Length: Le*, in. or mm

Terminal length: Lu*, in. or mm

Shank Spacing: A*, in. or mm

Specify Le, Lu and A with the same units (e.g. all 3 as in. or mm).

Examples:

Grade 1800, D1=3mm, D2=6mm, Le=5.5in., Lu=5in., A=.98in.

Specify as: MOSI2, 18-3/6-5.5-5-0.98in.

Grade 1700, D1=6mm, D2=12mm, Le=300mm, Lu=250mm, A=50m

Specify as: MOSI2, 17-6/12-300-250-50mm

Examples of typical MoSi2 element configurations.

Customers of MoSi2 elements enjoy two key added benefits – first, unparalleled price and second, experienced engineering support. Anyone can sell MoSi2, but knowing how to design the system is where excels. MoSi2 systems must be engineered for customer to get the best performance and optimum service life. Duralite engineers can assist in:

analyzing the relationship between the furnace temperature, element temperature and the element surface load

selecting the element surface load according to the furnace construction, atmosphere and operating temperature

choosing the most suitable element size and style for your application.