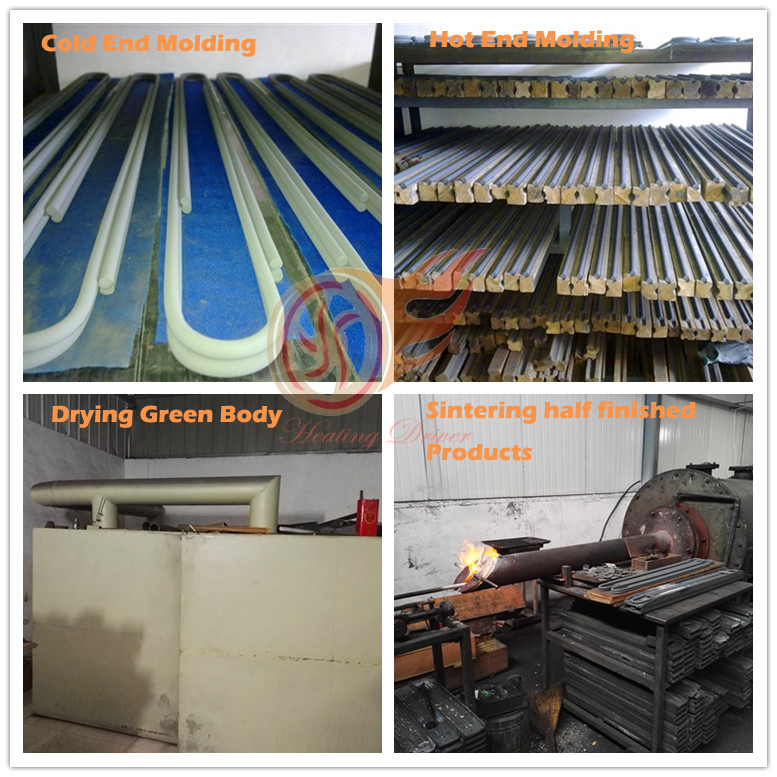

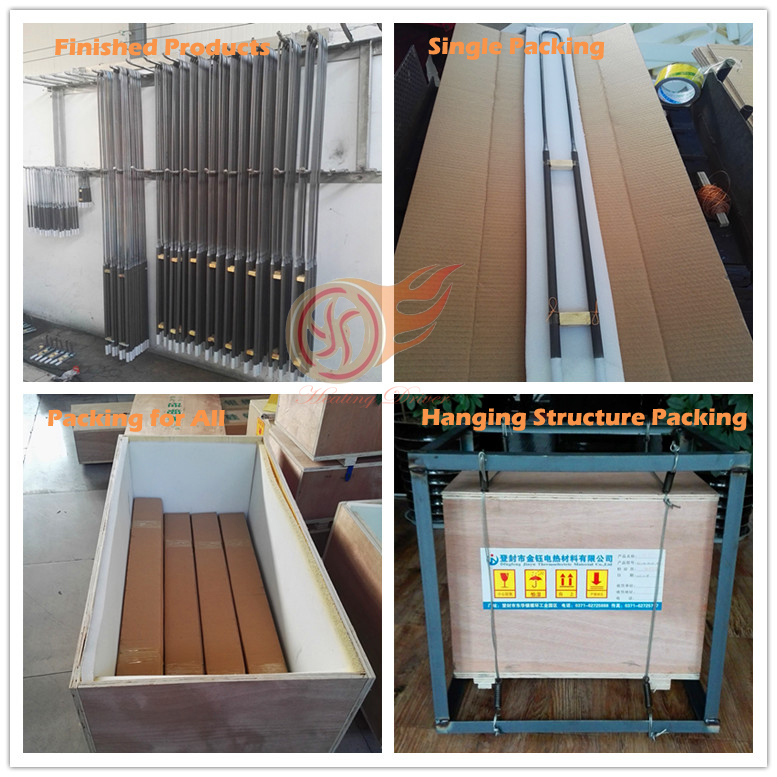

Production for Mosi2 Heating Elements

A production line for mosi2 heaters with a processing of sintering, bending and welding, is characterized in that: from 20 to 45% by volume of a clay mineral powder is added to the MoSi2 powder, followed by blending with water; and, the blended mixture is shaped, dried and sintered in non-oxidizing atmosphere at a temperature of from 1250 to 1550° C., thereby forming the above mentioned net-like microstructure of the silica-bearing oxide or glass phase and the network structure of the MoSi2 grains. In order to provide a heating element which is as dense as possible, (A) the MoSi2 powder having 5 μm or less of average particle diameter is used, and (B) the clay mineral having 1 μm or less of average particle diameter is used. These raw materials are blended with added water and shaped to the desired size by means of any appropriately selected shaping method. The shaped material is dried and then sintered in a non-oxidizing atmosphere, such as nitrogen, argon and the like, at a temperature of from 1250 to 1550° C. And the followings are general steps of the whole production line for mosi2 heating elements.