EQ1850 Φ4/9 U Type Mosi2 Heating Elements by Same Technology with Kanthal

$126.46 – $415.01

The electric parameters(Power, Resistance and Voltage, and resistance will vary under different temperature, so please don’t take these parameters as the ones under room temperature) for this element were tested under the following conditions:

Condition:

Temp. of Heating element: 1700°C

Temp. of Chamber: 1600°C

Current: 69 A

Surface Load: 12 W/cm2

Shank Space: 25mm

Description

Brief introduction for main products:

Main products we are running include: Molybdenum Disilicide Heating Element EQ1700, EQ1800, MR1800, EQ1850, EQ1900, The heating elements are high-tech products researched and developed by experts from China and other countries. Mosi2 heating elements can quickly form a thin and adhesive anti-oxidizing layer of quartz glass (SiO2) under high temperature oxidizing condition. If the protective layer was damaged, the element can reform a new one. So Mosi2Heating element has a very good properties of anti-oxidation, This means such heating elements can be used on operation for a much longer time than the traditional one.

The resistance of the Mosi2 heating element is not changing much as time goes on, so a new one can be installed without affecting the old ones, this can result of huge saving in furnace maintenance cost and time as well, and this is why Mosi2 heating elements can be better material and used widely.

Physical Properties:

| Density | Bending Strength | Hardness | Porosity | Water Absorption | Heated Elongation | Fracture Toughness | Compression Strength |

| 5.8g/cm2 | 350MPa | 12.0 Pa | ±2% | 0 | 4% | 4.5MPa.m1/2 | 650MPa |

Chemical Properties:

Mosi2 Heating Element has the ability of withstanding oxidation at high temperature. This is because of the formation of a thin and adhesive protective layer of quartz glass (SiO2) on the surface. The layer whose melting point is 1710°C will get fused into drops when it is over 1700°C due to the surface tension. However, SiO2 protective layer will rebuild again if the element continue working in oxidizing atmosphere.

Attention Please: It is not good to use Molybdenum Disilicide Heating Element for long run within 400-700°C, otherwise the element will be powdered by oxidation under low temperature.

Performances for different elements in different atmospheres:

| Atmospheres | EQ1700 | EQ1800 | MR1800 | EQ1850 |

| Air | 1700 | 1800 | 1800 | 1850 |

| Nitrogen | 1600 | 1700 | 1700 | 1750 |

| Argon, Helium | 1600 | 1700 | 1700 | 1750 |

| Dry Hydrogen, dewpoint -80°C | 1150 | 1150 | 1150 | 1200 |

| Moist Hydrogen, dewpoint 20°C | 1450 | 1450 | 1450 | 1500 |

| Mixed Gas(e.g. 10% CO25% CO15% H2) | 1600 | 1700 | 1700 | 1750 |

| Mixed Gas(e.g. 40%H2, 20%CO) | 1400 | 1450 | 1450 | 1500 |

| (8% H2)Cracked and partially burnt ammonia | 1400 | 1450 | 1450 | 1500 |

Resistance Properties:

Mosi2 heating element has good resistance characteristic, this is why it can be ideal heating element and replace traditional heating elements. The resistivity of Mosi2 heating elements is very low under room temperature(20°C), The resistance of Mosi2 Heating Element increases sharply as temperature rises, so it can heat faster and make consumption lower. Normally the resistance of the element won’t vary as time goes on, so new elements can be put into use with old ones.

Advantages of our Mosi2 heating elements:

- The element is anti-oxidation and can repair automatically, suitable for continuous use in all kinds of oxidizing atmospheres.

- Element is shaped in hot-working process, which keeps the bas material in good tenacity, plasticity, size and geometrical shapes, so we can produce any special shapes and dimensions according to customer requirement this way.

- We adopt special technology to weld the spot between cold and hot ends, which dramatically reduced the damage by electric current, and it is not easy to get cracked during transportation and installation.

- High density of EQ series have good electric conductivity, can heat rapidly and make low consumption, which reduce production cost for long run.

- Good appearance, tenacity and high mechanical strength.

Working Mosi2 Heating Elements:

- Mosi2 Heating Element is a kind of dense ceramic material, it is fragile and brittle under room temperature, so please take carefully during installation and transportation.

- The temperature of element EQ 1700 mustn’t exceed 1700°C, EQ 1800 element mustn’t exceed 1800°C when they are working continuously under oxidative atmosphere; and it should be keep below 1650°C for EQ 1700 and 1750°C for EQ1800 for intermittent use.

- Mosi2 Heating Element mustn’t work under 400-700°C for long run, or it will be damaged by strong low temperature oxidation.

Drying for Furnace:

It is necessary to dry it out for the first use of a furnace or a furnace doesn’t use for a long time, and usually temperature for drying is 100-200°C, there is low temperature oxidation for the elements, but several hours working under that temperature is enough and OK for small scale furnaces. However, it is a longer work for bigger scale furnaces, it is better to open the door at the beginning in order to ventilation, and then close the door slightly as the temperature rises, finally close door completely when it is 1000°C or above.

Start Up of Furnace:

It is ready to setup furnace for heating process if the drying work of the furnace has been finished, however, please control the voltage as following shows to avoid current overload:

| Small Scale Furnaces(Power less than 100KW) | Big Scale Furnaces (100-500KW) | ||

| Furnace Temperature °C | Voltage | Furnace Temperature°C | Voltage |

| 20-150 | 1/3 Working Voltage | 20-300 | 1/3 Working Voltage |

| 150-500 | 2/3 Working Voltage | 300-700 | 2/3 Working Voltage |

| 500-Working Temp. | Working Voltage | 700-Working Temp. | Working Voltage |

Replacement of Heaters:

Confirm location of the defective element first and meanwhile prepare new assembled heating elements. Then unbolt the contacts from the busbars and remove the ceramic fiber around the upper part of the passage brick, pull out the element and the passage brick together and then put the new assembled element into position from the hole in the furnace roof.

Additional information

| Weight | 1.2 kg |

|---|---|

| Dimensions | 700 × 300 × 40 mm |

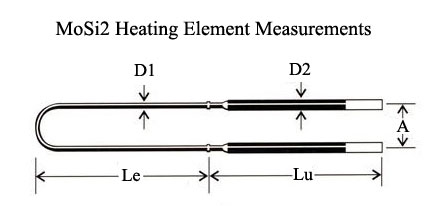

| Le/Hot Zone (mm) | 75, 100, 125, 140, 160, 180, 200, 225, 250, 280, 315, 355, 400 |

| Lu/Cold Zone (mm) | |

| Shank Space |

Reviews

There are no reviews yet.