Additional properties:

Maximum temperature: 1650 ¡ãC.

Coefficient of thermal expansion (25 ¡ãC to 1000 ¡ãC): 8.0 x 10′ / ¡ãC.

Compressive strength: 2500 MPa.

Specific Gravity: 3.92 g / cm3.

Hardness: 1440 Kg / mm2.

Permeability: impermeable to gases.

Advantage:

High density, high purity.

Good wear-resistant, sealing ability.

Good tensile strength.

Good high temperature tolerance.

Excellent cold crushing and thennal shock resistance.

Excellent chemical stability and corrosion resistance.

No staining for long-term use.

Excellent insulating ceramic material.

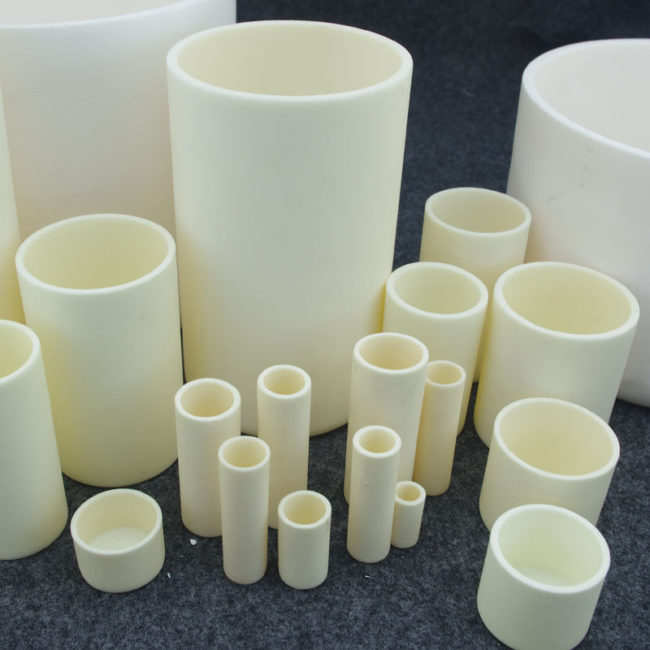

Application:

Wildly used in all kinds of laboratory analysis and various industrial analysis, metal and nonmetal material sample melting.

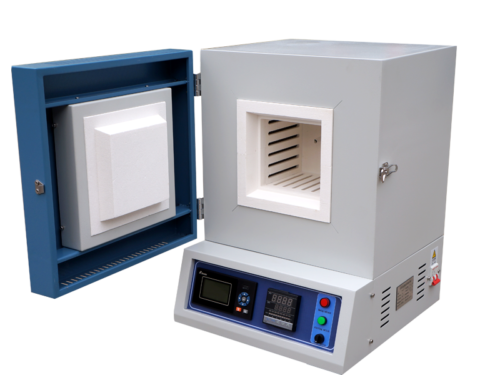

Widely sued for high temperature application, like metal processing, glass melting, rapid thermal cycling, gemstone purification for jewehy industry.

Widely applied in the metallurgy, chemical industry and materials science, etc.

Please Note: These are precision technical ceramic components. There is no warp or camber on these items. They are straight and round. The thermal shock resistance is not very high so exercise rule of thiunb caution. “The larger the piece of material the slower the rate of temperature increase should be applied to the piece.’ Heat up slowly to avoid cracking in use.

Alumina crucibles are made of aluminum oxide 99.5% purity. These products are highly resistant to chemical attack and are especially useful for jobs that require high tempe be sued in reducing, oxidizing and vacuum atmospheres. They are inert under hydrogen atmosphere and are highly resistant to alkaline media and have excellent resistance to abrasion and wear. ratures pollution-free results.

Matters needing attention:

Ahunina products are fragile. They must be handled with care and avoid collisions during handling. Check the product to check for any cracks, in which case they should not be used.

Ahunina products must be dry before use. If drying is done in ovens, make sure the process is carried out slowly. Avoid contact of hot product with cold surfaces alumina. Ahunina products should not be heated in ovens or furnaces without flame control heating rate and heating rate cannot be 50t /10mins. Besides it cannot be used over 1700¡ãC. The uneven heating may cause its cracking.

FAQ:

How to order ceramic tubes?

You can tell me your detail size. You’d better send me the drawing.

What is the delivery time?

If we have the size you need in stock. We will send them 2-3 days, if you order crucible need to produce, the delivery time is about 10-25days.

Shall we supply samples?

Yes, we can supply the client samples in stock.

Which country we usual sell?

We usually sell our products to USA, Japan,UK,France,Russia,Gennany,India,Spainsh,etc many countries in the world.

What is our payment term?

As the client need, we mainly receive TT,West Union,Paypal,etc.

Contact us:

If you require additional technical information, design, or application engineering consultation, feel free to contact us. We will provide you with creative and imaginative approaches to your requirements as soon as possible.

We can supply the products according to customer’s drawings, samples and performance requirement. You can contact us through email: frankciao@gmail.com

Reviews

There are no reviews yet.