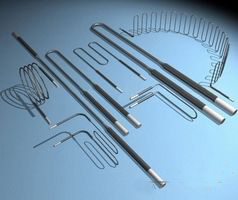

DB SiC heating elements

Type DB Dumbbell – (Enlarged Cold End) – Silicon Carbide SiC Heating Elements

One of the earliest heating element designs, the enlarged cold ends of the DB type SiC heating element were originally made oversized to increase cold end cross section, lowering electrical resistance, thereby lowering cold end operating temperature. Modern DB by contrast, employ an advanced technology to keep the terminal ends cool by virtue of the decreased resistivity of the lower resistance cold end material used in the manufacturing process. Oversize cold ends are therefore no longer necessary. DB SiC heater can be substituted for Dumbbell . The old style resistance ratio was 1:3, whereas the new DB SiC heater resistance ratio is 1:15. Maximum temperature is 1600 deg C.

The first several inches of the cold ends are metalized with aluminum to provide a low-resistance contact surface. Electrical connections are made using flat aluminum braids, held in compression to the cold end circumference by stainless steel spring clamps.

DB SiC heater are described by giving the overall length, the heating section length, the hot zone outer diameter and the cold end outer diameter.

DB type SiC heater standard diameter

| Diameter of HZ(mm) | 8 | 12 | 14 | 18 | 25 | 30 | 35 | 50 |

| Diameter of CZ(mm) | 14 | 18 | 22 | 28 | 38 | 45 | 50 | 60 |

OD: Cold diameter, HZ: Hot zone, CZ: Cold zone, OL: Overall length, Resistance: Ohms (Ω)

d: dia of hot zone, Examples: DB, dia (OD/d) / hot zone length / Overall Length/ resistance

DB 8/14 / 150 / 450 / 2.24