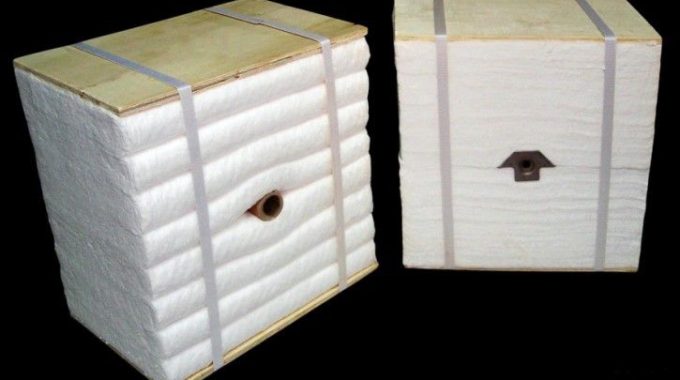

CERAMIC FIBER MODULE

CERAMIC FIBER MODULE are manufactured from ceramic fiber blanket to provide two standard construction forms, edge-stacked or folded. These prefabricated anchored modules are specifically designed to meet the thermal insulation requirements of industrial furnaces, kilns and heaters.

Property

Low thermal conductivity & heat storage

High temperature stability

Resistance to thermal shock & chemical attack

To be secured by concealed anchor

Greater mechanical strength

Resistance to gas flow erosion

Shorter heat up and cool down time

Flexible and easy to cut or install

Selection of attachment designs

The expansion of module make furnace lining be seamless and can make up the shrinkage of fiber furnace lining to improve heat insulation

Excellent tensility, after the construction of furnace lining is completed; The module is at the

pre-compressed state;

Lightweight & Asbestos free

Typical Application

Insulation of furnace lining in petrochemical industry

(Heating, Reformer, Cracking Furnace)

Insulation of furnace lining in metallurgy industry

Insulation of furnace lining in ceramics (Shuttle kilns, Tunnel kilns, Kiln cars)

Insulating of furnace lining in glass industry

Insulation of furnace lining for heat treatment furnace in heat treatment industry

Material of furnace lining for Heating, Forging, Annealing Furnaces

Iron and Steel Industry: Reheating furnace, Multi and single stack coil annealing furnaces,

Transfer ladle lids, Continuous annealing and coating furnaces, Roll furnace.

Waste heat recovery units, Combustion Chambers, Boiler ductwork

| Product Grade | |||||

| Grade | 1260 Module | 1430 Module | 1500 Module | 1600 Module | |

| Classification Temperature | ° C | 1260 | 1430 | 1500 | 1600 |

| Max Working Temperature | ° C | 1100 | 1280 | 1350 | 1580 |

| Melting Point | ° C | 1760 | 1700 | 1760 | – |

| Chemical composition | |||||

| Grade | 1260 Module | 1430 Module | 1500 Module | 1600 Module | |

| A l 2 O 3 | % | 47.1 | 35 | 40 | 72 |

| S iO 2 | % | 52.3 | 49.7 | 57.8 | 28 |

| ZrO 2 | % | – | 15 | – | – |

| Cr 2 O 3 | % | – | – | 2.0 | – |

| Physical Properties | ||||||

| Grade | 1260 Module | 1430 Module | 1500 Module | 1600 Module | ||

| Density | k g / m 3 | 160-190-220 | ||||

| 160k g / m 3 | 160k g / m 3 | 160k g / m 3 | 160k g / m 3 | |||

| Thermal Conductivity W/(m. K) | 400 | ° C | 0.09 | 0.09 | 0.09 | 0.09 |

| 600 | ° C | 0.14 | 0.14 | 0.13 | 0.13 | |

| 800 | ° C | 0.21 | 0.21 | 0.17 | 0.17 | |

| 1000 | ° C | 0.28 | 0.28 | 0.22 | 0.20 | |

| Li n e a rShrinkage( ° Cx24H) | % | 1100 ° C—1.0 | 1300 ° C—1.5 | 1400 ° C—1.7 | 1500 ° C—1.0 | |

| Color | White | White | Blue-green | White | ||

| Available Size | |||||||

| Grade | Compression Size | Highness Size | Thickness Size | Unit | |||

| 1260 Module | 300 | 300 | 150 | 200 | 250 | 300 | mm |

| 1430 Module | 300 | 300 | |||||

| 1500 Module | 300 | 300 | |||||

| 1600 Module | 300 | 300 | |||||

Ceramic fiber module products